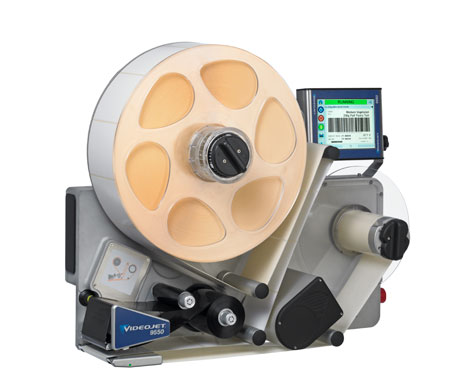

Print & Apply Labeler 9550

Maximize your line uptime, increase productivity and remove the risk of mislabeling packages with the Print & Apply Labeler 9550

The Print & Apply Labeler 9550 with Intelligent MotionTM is a smarter print and apply labeler that targets zero unscheduled downtime and reduces costs and errors in case coding operations.

- Optimizes maintenance labor by eliminating more than 80% of wear parts

- Never miss a label, with self-adjusting label placement to accommodate varying line speeds, throughput and package sizes

- Minimize misapplied and snapped labels with on-demand Direct Apply using no plant air

- Improve throughput during build-back with Direct Apply labeling up to 150 packs per minute

- Minimize operator touches with on-board label database for accurate job selection

Operational downtime caused by label jams and routine manual adjustments is removed through Intelligent Motion Technology, which automatically and precisely controls the entire system. In addition, Direct Apply™ is a unique on-demand labeling method that allows accurate placement of the label onto the package without the need for an applicator – even at high speeds.

Whether it is a belt, a roller or another kind of conveying system: the Print & Apply Labeler 9550 can be mounted on all conveyors from sfb Fördertechnik.

Conveyor and marking solutions from one source – benefit from this strong partnership today!