VERTICAL CONVEYOR / LIFT

BYPASS LEVELS IN SMALL SPACES

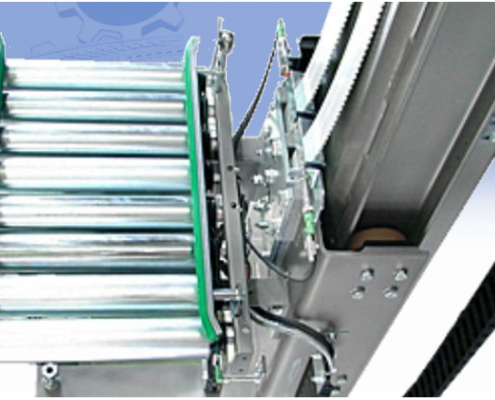

A vertical conveyor consists of a lift pole, a drive unit and a lifting car on which a conveying component is mounted.Our vertical conveyors are made in a sturdy welded design. Two steel profiles are mounted on the sides which act as guides at the same time. The lift is guided by Vulkollan wheels through these guides. On the extension arms of the lift, different conveying systems can be mounted, like, for e.g., chain conveyors, roller conveyors, belt conveyors, etc. The lift drive (frequency controlled gear motor) is positioned on top of the lift frame and drives two timing belts. The timing belts are circumferential and fixed on the lift and on the counter weight. In order to reduce the motor power, a counter weight is installed which has a mass of 50% of the theoretical net load and assists the lift drive. On each timing belt, the timing belt tension is controlled by a sensor. The whole vertical conveyor is secured by fences all over. Merely the feed and outlet openings are secured according to the product dimensions. The doors of the safety fence are secured via safety limit switch.

Special features:

- Lift frame

- Adequate for different conveying systems

- Supported lift drive via counter weight